Topics Covered

3-1 Comparable and inspection-able geometry specification

Calculation of Angle, Center of Gravity, Distance, Area, Distances and angles (trigonometric functions), Cartesian and polar coordinates, Limits of maximum inscribed and minimum circumscribed calculation for segments smaller than 180°. Limits of coaxiality of concentricity and possible alternatives, Measuring small circle segments, crowing, Function- and inspection-compliant design, Cost-reducing design, Dealing with ambiguous drawings, Digital inspection planning

3-2 Production-compliant Inspection

Production Types and Achievable Production Precisions, Form Deviations and Their Causes, Measuring deviations

3-3 CAD Basics

Principles of Construction and Technical Drawing, Principles and Tools of CAD Design, Imaging of Geometry, Model Types, CAD Data Dimensions, Import of CAD Data, Interfaces

3-4 Point Cloud and Reverse Engineering

Point clouds, STL data, Nominal-actual comparisons, Basics of reverse engineering, Creating geometric elements via reverse engineering, Reverse engineering in practice, Data formats

3-5 Automated measurement program generation (PMI)

Types of automated generation of measurement programs, Fully parameterized workpieces, Workpieces with product and manufacturing information (PMI, “3D tolerances”), Tasks and responsibilities of the measurement engineer for the automated generation of measurement programs

3-6 Digital Filtering and Evaluation

Software Filters, Gauss Filters, High-Pass, Low-Pass, Waviness, Roughness, mechanical filter, morphological filters, Dealing with outliers

3-7 Communication

What is communication? How does communication work? Cultural values, Positive formulation, Benefit/gain argumentation

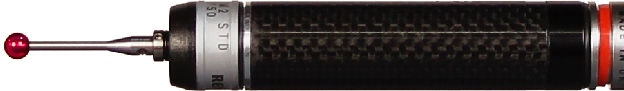

3-8 Sensor Competence

Planning measurement strategies, Criteria for the determination of the measurement strategy, Criteria for the selection of sensors, Effect of different strategies on the measurement result

3-9 Monitoring of CMMs

CMM Monitoring, ISO 10360/VDI 2617, Possibilities to optimize the accuracy of CMMs, Calibration, calibration chain, traceability, normals, monitoring, acceptance test, verification, calibration, process capability, influence of temperature and coefficient of expansion

3-10 Measuring Uncertainty and Measuring Process Suitability

GUM Handbook, Determination of the Measuring Uncertainty, Uncertainty Budgets, PUMA Method, Increasing Measurement Uncertainty, Extended Measurement Uncertainty, Conformity, ISO 14253, Determination of Uncertainty Using Calibrated parts, Use of the Virtual CMM, Measuring Process Suitability according to MSA (GR&R), VDA 5, Comparing the methods

3-11 Quality Management

Quality Management Standards, Audit and Certification, Quality Tools, Origin of Errors and Error Elimination, Optimizing quality costs, Influence of design and inspection on the quality costs

3-12 Process Monitoring

Process Monitoring, Statistical Process Control (SPC), cp Values, cpk Values, cm Values, cmk Values, Monitoring Strategies and Quality Control Cards, Capability studies and their relevance to the overall process

3-13 Measuring Room Management

Aspects of measurement room management as a whole, Planning, procuring and operating measurement rooms, Work procedures in a measurement room, Tools and methods for controlling the processes in a measurement room, Personel selection, qualification and further development

3-14 Conclusion

Influences on the measurement result, Influence of measurement uncertainty on process parameters, Job profile Metrologist