When a large automotive manufacture reached out to us for a reverse engineering project with an engine block, we knew we had a big project on our hands…literally!

Our customer’s team didn’t have the original drawings for the engine and the manufacturer no longer makes the engine they needed to keep this part alive for the future. They knew they had to reverse engineer the engine block with the ones they had left in their facility. After conversing and establishing what was required by the auto manufacturer, our experts got to work. Our metrology team came together to collaborate and plan the meticulous and detailed process of sectioning, scanning, and repeating the steps until all the necessary pieces were complete.

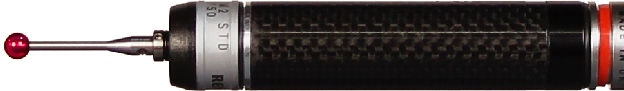

We started with the overall measurements of the entire part. We did a full article inspection to get the overall dimensions to allow us to move forward with the planned process. Our metrology experts used our Apache CMM to take hits with the CMM and gather all of the fundamental data. Then, with help from our machining department, they strategically cut off layer-by-layer the sections of engine block, exposing the next slice of the series. Slice, scan, repeat. Manually “CT Scanning” is one way to look at it!

Once our metrology team had all of the critical scans and dimensions, they pieced together the scanned layers to create 1 solid, unified model. After a thorough review, the 3D model was complete. The customer was able to use the model and drawings to produce the engine block that is no longer manufactured by the original maker.