A well known manufacturer of writing utensils is currently in the process of reshoring their manufacturing operations back to the United States & their branding team is holding up the release of the product, but why?

In our customer’s efforts to grow manufacturing back on American soil, the team went through the process of reverse engineering and recreated their product for mass production. Once assembled, the final proofing from their brand management team is a must. They distributed the pens for brand testing only to find out they had one problem- the team unanimously agreed, the pens click wasn’t satisfying.

Imagine, you’re sitting down to write with a brand new set of pens from your favorite company. Brand new plastic, smooth writing ability, but when you click the top of the pen, it just feels off. As a customer, your initial reaction may be that this doesn’t really matter, but to their customers, it will make or break their purchasing decision.

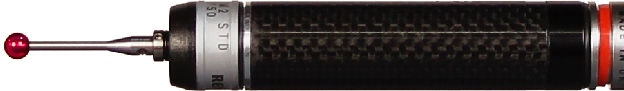

Time for our metrologists to diagnose this problem. At Made to Measure, we met face-to-face with our customer who brought us two batches of parts, one from the USA and one from China. We discussed the situation and determined necessary areas to be inspected on both batches for comparison. Next, the customer’s problem became our job and the metrologists put their measuring skills to use!

After our easy-to-use report was sent, our customer found a solution to their manufacturing issue. As it turned out, they discovered some differences in the clip housing geometry when results were compared. They were able to adjust the tooling and the function is greatly improved! Browse our services to see how we can help find you solutions today!