Legacy CMM: Blackhawk

The following information is for a legacy product. If you would like to learn more about our range of new coordinate measuring machines, we direct you to our AccuFLEX line of CMMs!

Blackhawk: Our Benchmark CMM Machine

Equipped with the latest technology, the Blackhawk offers efficient thruput for a lower cost of ownership than many other major CMMs on the market.

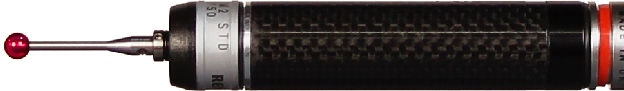

The Blackhawk is Made To Measure’s mid-level machine equipped with a PH20 head for increased range of motion and 5-axis head orientations, that aren’t achievable with 3-axis systems. All Made to Measure CMMs come standard with Renishaw’s ultra-fast MODUS software! With increased throughput and capacity, your team will achieve reduced cycle times, allowing you to inspect quickly and accurately. Great for the automotive industry, as well as companies with a focus on high-volume production.

The Made to Measure CMM custom workstation is included with every purchase of a new CMM machine.

Blackhawk CMM Machine Sizes In-Stock:

6.10.5 (600mm x 1000mm x 500mm)

8.10.6 (800mm x 1000mm x 600mm)