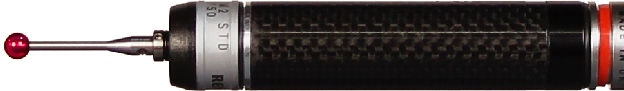

Touch Probe Scanning

Touch Probe Provides Accuracy and Repeatability

Touch Probe Scanning provides a continuous deflection output that can be combined with the machine position to derive the location of the surface. When scanning, the probe stylus tip is brought into contact with the feature and then moved along the surface, gathering data as it moves. In some instances, this form of technology can be more accurate and offer increased repeatability in a controlled environment.

Scanning provides a fast way to capture form and profile data from prismatic or complex components. This method of measuring is especially useful with partly transparent or reflective materials as the probe and styli travel all around and inside the object being inspected, gathering data from every angle through direct contact with the product.

Touch Probe vs. Laser Scanning

Laser and camera systems have made huge strides in the last decade, and are certainly the future of measuring. However, touch probe scanning has several distinct benefits and the two should be considered complementary technologies.

- Ten times more precise- to within .0001”.

- Ability to export raw CAD data in dxf, igs, and stp files.

- Eliminates the risk of data overload.

- Read more about touch probe vs. laser scanning!