Reverse Engineering

Reverse Engineering services are used for a number of purposes throughout many industries. Oftentimes manufacturers have an operational part, but lack a model, drawing, and tooling. Reverse engineering is an extremely effective method of producing 3D CAD models or 2D drawings from an existing component. At Made to Measure, we can evaluate and measure every aspect of your component in order to develop the essential drawings & 3D models needed for manufacture.

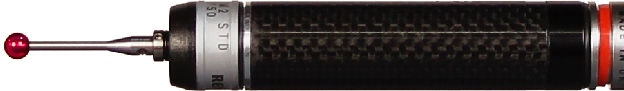

Using a combination of 3D laser scanning, touch probes, scanning probes, and hand tool measurements, we can readily replicate physical parts with a number digital formats. Scanned data shows the current state of components current state, and often serves as baseline for new product development. Do you need to update old drawings? Were they simply lost to time? Do you need to design all-new tooling from a prototype? When you need to reverse engineer a model or drawing from a part, Made to Measure is ready to provide the metrology solution you need.

Reverse Engineering can help:

- Establish a reliable 3D CAD Model

- Reproduce an outdated or obsolete part or product

- Advance your team’s product or part development

- Investigate design that can be improved or modified

- Innovate an existing part or product design

- Repair obsolete equipment

What is the Reverse Engineering process?

1. Analysis of the Part and Deliverables – Before we provide an estimate for your reverse engineering project, our Metrologists first analyze the intricacies of the component. Upon inspection, our Metrologists will determine if the deliverables required by the customer coincide requirements for output and accuracy. Additionally, the Metrologists review the project deliverables against our capabilities to develop the best possible solution. If the objectives don’t align with our core competencies, the Metrologist will recommend not taking on the project.

2. Capturing Physical Part Data – After we analyze the part, we capture the measurement data needed to create the 3D model utilizing either a CMM-based Nikon laser scanning system or our hand-held Creaform MaxSHOT laser scanner. With these high-data, high-accuracy collection laser scanning devices, we can quickly and reliably collect the data to complete your model in a timely manner.

3. Data Processing and Model Creation – During this stage, we edit, refine, and tailor measurement data for the next step of the Reverse Engineering process. We then prep the data for reverse engineering based on the accuracy and efficiency needed. Lastly, we format measurement data according to the customer’s desired output and preferred reverse engineering process.

4. Final Review – Once complete, our Metrologists verify that the CAD model is accurate to the measured data. A comparison between the measured data and the CAD model is performed using the same color map analysis process that we use for inspection. Once we verify the results, we send the 3D model to the customer so they can begin new product development and manufacturing. With the verified model, we can also provide a 2D fully-dimensioned drawing.

Reverse Engineering with CAD Models

Laser scans produce a point cloud or a polygon mesh which is ideal for reproducing CAD models for tooling, molds, dies, products, and components. 3D Surface Modeling (also known as surfacing) places a surface on your point cloud of data, essentially building a new visual model for your product.

Made to Measure utilizes PTC Creo Parametric (formerly Pro Engineer), Solidworks, and GeoMagic Design-X modeling with conventional surfacing tools, as well as those included with the special Reverse Engineering Extension, to create a three-dimensional, fully-surfaced product on the screen, so you can visualize your product in its entirety. The extension allows our technicians to import point cloud data, transform it into a triangulated mesh model, and subsequently model both free-form and analytic surfaces, using the mesh model as a three-dimensional reference.

Reverse Engineering Services Can Include:

- Updating or creating new 3D CAD Models

- Producing 2D fully-dimensioned drawings

- Generating Surface Models and Parametric Solid Models

- STL file creation

- NURBS file creation

- Color Map analysis and report generation (Part of our Inspection Services)

3D Laser Scanning Services

The 3D laser scanning process for reverse engineering yields outputs in one of several major categories. Each of these derivatives offer unique benefits, and each customer may have different needs. As such, the deliverable is customized to meet their exact requirements. To help you understand the differences in each model and the applications they are best suited for, take a look at the chart below.

| Output | Point Cloud | NURBS Surface Model | Hybrid Model | Direct Model | Class-A Surface Model |

| Overview | Raw Data | Exact Model of Surface | Combination of Features & Surface Patches | Feature-Based w/ No Connections | Highest Surface Quality Level |

| Price Level | $ | $$ | $$$ | $$$$ | $$$$$ |

| Key Characteristics | -Raw data as collected from the measurement device -Basic XYZ coordinate data -Minimal data editing performed -Basic building block on which subsequent files are based | -Captures as-built state -Includes manufacturing defects -Non Class-A surface finish -Static IGES or STEP surface model -Patchwork of small surfaces | -CAD data converted from scan data -Can ignore or incorporate manufacturing defects -Export IGES (STEP…) surfaces or solid -Modifications require re-trimming | -Can be used in any CAD system, even feature-based systems -Works with raw geometry -Quicker and easier to combine with other 3D model formats -Easier to rework and modify | -CAD data converted from scan data -Freeform surfaces of high efficiency and quality -Surfaces have curvature and tangency alignment -G2 or G3 curvature continuity |

| Typical Applications & Notes | -Expert care is needed when dealing with only raw data files | -Captures as-built state (exactly) -Includes manufacturing defects -Patch-work of surfaces -Very good for free form shapes such as hand formed surfaces, artistic elements, and parts difficult to model in standard CAD packages | -Few modifications to the file are needed -Exchange file format -2D drawings are needed -Surface finish must be smooth | -Feature-based geometry -Design intent -Simulation -Rapid design change | -Feature based geometry, design intent -Used when model will be modified -2D drawings are needed -Surface finish must be smooth |

| Common File Types | .stl, .asc, .xyz, .obj | .step | .stp, x_t, .iges | .stl, .step | .stl, .asc, .xyz, .obj |