3D Laser Scanning

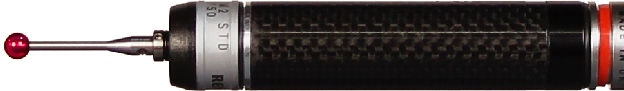

3D Laser scanning is a non-contact, non-destructive measurement technology that digitally generates 3D point cloud data, ultimately turning your physical parts/products into a digital representation of the physical object’s exact size. Our CMM-based laser and Portable Scanning Arm systems can capture an abundant amount of precision data(in comparison to some traditional methods).

Our experience in 3D scanning services ranges across a broad spectrum of industries. From Aerospace and Automotive scanning to Medical devices and supplies, we take care of 3D laser scanning parts that require high degrees of accuracy.

Typical applications for quality Laser Scanning:

- Part to Part Comparisons

- Repairing Tools

- Data Archiving of Legacy Parts

- Rapid Prototyping

- First Article Inspection

- Reverse Engineering

- New Part/Product Development

- Part to CAD Comparisons

- Quality Control

Scanning makes measuring complex parts simpler and faster than ever before. By capturing detailed point cloud data through laser scans, we are able to inspect your most intricate parts. 3D laser scanning allows designers and manufacturers to see a visual representation of geometric features and free-form surfaces of their parts/assemblies. With 3D laser scanning services, Made to Measure can help your team resolve issues and make design improvements with detailed feedback.

In-House CMM-Based Laser Scanning

How can 3D scanning help your business? Made to Measure’s CMM-Based 3D Laser Scanning expertise can aid your company in tackling quality bottlenecks, design modification recommendations, and much more.

On-Site Laser Scanning

Need our 3D Laser Scanning services at your company’s facility? We offer 3D measurement for on-site installations, use-case demonstrations, large-scale reverse engineering, and more! We understand the logistic difficulties and additional cost involved when shipping large, heavy, and unique parts. Made to Measure provides On-site Laser Scanning for this very reason! So whenever your projects aren’t as mobile a one of our certified metrologists, we can ship our team to you instead. We’ll come to you and perform the scans, saving you time and unnecessary headaches.

See how on-site laser measurement can help you save on logistics, shipping wait times, costs, and more! Reach out to us today and see how we can work with you to take care of any 3D scanning services you need.

3D Laser Scanning Capabilities

- Capture shape, size, color, and surface details

- Accurate to .002″

- Export to CAD model

- Editable digital design format

Industries Served:

Aerospace/Avation

Automotive

Castings

Fixture Design/Manufacturing

Locomotive/Railway Industry

Machinery Manufacturing

Metal Fabrication

Medical Devices/Supplies

Tool & Die

First Article Inspection

For inspection applications, a point cloud comparison to the CAD model can provide an excellent overall picture of the parts conformance to the actual design. Since the entire part is digitized, nothing is overlooked. Dimensional deviations, errors in form, features out of place, or missing features are just some of the defects that can be found. This type of inspection can be very useful for tooling approval or deciding whether a part and process is ready to begin PPAP.

Reverse Engineering

Reverse Engineering applications can range from totally new products to those that have been in production for many years. For new products, laser scanning can be used to digitize clay models or fabricated models with the resulting point cloud data used to create a CAD model. Laser scanning and reverse engineering also comes into play with current or past production pieces that require new tooling and the databases aren’t available or do not match the current configuration of the part.

CAD Modeling

For modeling applications, 3D Laser scanning is an effective and efficient way to get your part into a CAD Model! How does it work? You send your part(s) to our facility. We receive and scan them in our lab. Our scanner creates a point cloud file that we turn into a CAD model during the post-processing phase. Once the CAD model is created, it’s reviewed and digitally sent off to your team for the next leg of the journey. Whether it be for improvement of parts, flaw detection, or even an update to your internal documentation, we’ve got you covered.