Large Scale Inspections

Are you manufacturing large parts, too big and heavy for your own CMMs to handle? Big parts require big inspections — With our large-scale precision measuring equipment, including our Gantry CMM and 3D Scanners, we can accurately measure your sizeable parts effectively and efficiently. We closely collaborate with you to understand your objectives and deliver the data you need in our easy-to-read inspection reports. From First Article Inspections to CMM Programming, we’re your go-to full service metrology lab.

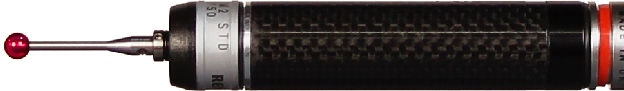

Large CMM Measurements

Gantry CMMs are designed specifically to measure large-sized precision components with speed and accuracy. Our Large Scale Gantry CMM can measure large parts, up to 524 cubic feet. The gantry coordinate measuring machine is mounted into it’s own unique foundation, allowing for the most precise measurements, isolating the surface from any outside vibrations. Our metrologists are highly-experienced with large parts inspections and customize solutions to fit your needs.

Capacity

- Travel XYZ: 78″ x 197″ x 59” (2000mm x 5000mm x 1500mm)

- Max Part Size: 110” x 250” x 65”

- Weight Capacity: up to 20,000 lbs; 10,000 lbs internal crane & forklift capacity.

(Riggers are required for parts over 10,000 lbs)

Our Large Scale CMM services are ideal for large aerospace castings, wind turbines, machined parts, and more. Our Metrologists have a vast array of experience in many different industries with over-size parts and assemblies. When you need a reliable solution for inspecting your large parts manufactured, rely on Made to Measure!

Large Scale CMM Services Include:

- First Article Inspections

- Partial Inspections

- Reverse Engineering

- Checking Fixtures

3D Scanning for Large Parts

3D Laser Scanning for measurement processes are firmly established in the metrology world. These technologies offer the ability to collect a large amount of data in a relatively short period of time. Our team is ready to scan your parts with our CMM-based Nikon laser scanning system or the ScanTech TrackSCAN laser measurement system. With these high-data, high-accuracy laser scanning devices, we can quickly and reliably collect the data you need for your next inspection. From CAD-Deviation Analysis to Reverse Engineering, we’ve got you covered.

Capacity

- Max Part Size: up to 10m

- Measurement Accuracy: 0.0017” + 0.00018”/ft

- Weight Capacity: up to 20,000 lbs; 10,000 lbs internal crane & forklift capacity.

(Riggers are required for parts over 10,000 lbs)

3D Laser Scanning Services for Large Parts Include:

- First Article Inspection

- Partial Inspections

- Reverse Engineering

- Part to CAD Comparisons

- Part to Part Comparisons

- Repairing Large Machinery

- Data Archiving of Legacy Parts

- Rapid Prototyping

Call us to discuss your next project today! 847-851-1160

Just Some of the large scale parts we’ve measured:

- Aircraft Components

- Wind Energy Turbines

- Gear Boxes

- Large holding fixtures

- Shafts

- Industrial Gear

- Missile Cones

- Space Parts

- Locomotive components

- Racecars

Contact us today to discuss your next large scale measurement project!

View this post on Instagram

View this post on Instagram