Finding the Right CMM for You

Purchasing a coordinate measuring machine (CMM) is no small endeavor, as it’s a highly specialized, extremely technical piece of machinery. Do you need the warranty and performance that comes when you buy a new CMM? Or do you prefer the affordability of a rebuilt and retrofitted CMM for sale? Do you need a bridge CMM? What about a horizontal CMM or a shop floor CMM? Made to Measure is always ready to help you answer these questions and more! Read on to help you narrow down your options when searching for the best CMM for your measurement needs.

What size parts are you measuring?

The first step towards finding the right CMM is determining the proper size for your application. Typically you want to try to fit 80% of the parts you make in the measuring envelope of the machine. The measurement envelope of a coordinate measuring machine is the space in which the X, Y, and Z axis can reach and measure a part placed on the granite. Typically, the measurement envelope is found somewhere visible on the machine and separated by periods (ex. 10.10.8 or 20.12.10).

While it would certainly be nice to fit every part you produce, fitting the last 20% doesn’t always warrant the additional cost of a larger machine. However, those who only plan on inspecting a single part or a limited range of parts may benefit from a machine capable of measuring their whole catalog.

What are your tolerances for these parts?

The answer here provides great insights, as it will determine how accurate your perfect CMM needs to be. For example, if you need to measure stamped sheet metal parts, then a shop floor CMM is plenty accurate enough for your needs. However, if you’re producing gears for a transmission, then a high-accuracy CMM is much more appropriate. There are even cases where a programmable gage, such as the Renishaw Equator, makes more sense for your dimensional inspection needs.

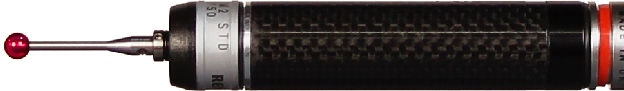

It will also help to determine what sensors are required for the best CMM for you. For example, a manual indexing head offers repeatability of 2.5 microns while a motorized head can achieve as low as 0.5 micron repeatability.

What are your thruput requirements?

While the previous two questions will help narrow down the CMM size and CMM type that’s right for you, your thruput requirements will mostly determine the probe head you need. With the PH20 5-axis touch trigger head or the REVO 2 5-axis scanning head, you can run twice or even three times the thruput of a traditional three-axis CMM. Because 5-axis heads require far less movement to take far more measurements.

Need to see it to believe it? Take a look at this video of our REVO 2 in action to get an idea of the speed it’s capable of, or come in for a demo! Contact us or call 847.851.1160.

Who will run your CMM equipment?

This is software related. We have multiple software solutions, so we will custom-tailor the solution for you. CAD? SolidWorks? CATIA? Embedded Dimensions? Nothing but a PDF? No problem! We have a software solution for you!

Find the Right CMM for You at Made to Measure!

Whether it’s a brand new AccuFLEX bridge CMM or a freshly retrofitted and refreshed used CMM for sale, our team at Made to Measure will help you take home the measurement equipment you need to enhance your quality department. Give us a call at 847.851.1160 or send us an email today to get started.