Tuesday, August 8th, 2023

ASME Y14.5-2018 vs ASME Y14.5-2009: Compare ASME Standards

Below is a highlight of handful of changes at first glance.

Contact us: info@measure911.com | (847) 851-1160

Below is a highlight of handful of changes at first glance.

https://transparency-in-coverage.uhc.com/

Metrology terms can be a bit intimidating, especially considering that anytime you mention Metrology in a casual setting, you inevitably get asked about the weather—“did you mean meteorology?” Metrology is the study of measurement, and at Made to Measure, we’ve performed

Read More

Promotional Pricing Extended Through June 18th, 2021

A customer had an unfortunate problem with the production of their petcock fuel valves for off-highway vehicles. The team at Made to Measure found them a solution!

Measurement results are influenced by many factors, but here’s 5 easily avoidable errors you can prevent on your next inspection.

The International Manufacturing and Technology Show comes around once every two years, will you be there?

You don’t need to be a Metrologist to understand that taking measurements happens all the time!

Imagine a world where your engineering, manufacturing, and metrology department were all on the same page about drawings, tolerances, and GD&T. Where your inspection results are produced seamlessly by each metrologist and are comparable across your entire team. A world

Read More

Metrology isn’t relegated to a far-off world of formulas and programs, it touches every day life – from tiny gears and fittings to fun and games!

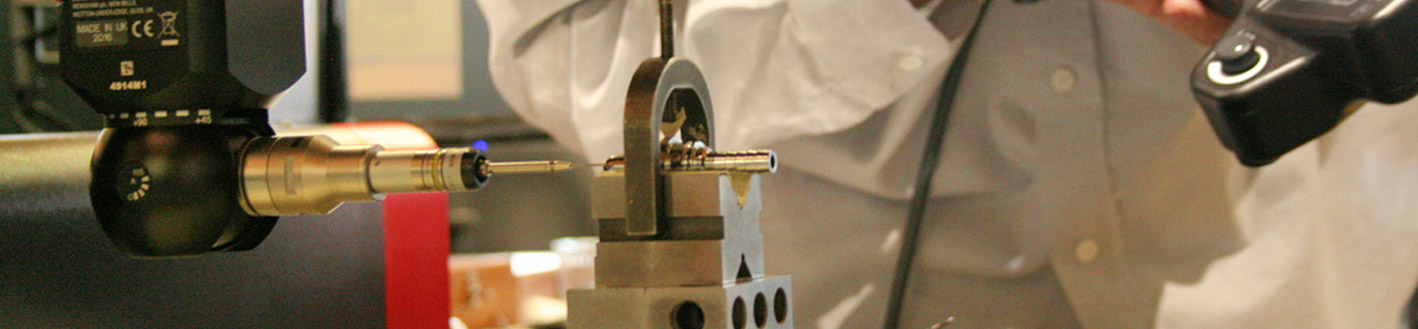

Our Metrologist and precise CMMs get the results you need, like for this high precision housing. This machined pump housing needed careful handling along with temperature control as the tolerances were tremendously close.

A customer needed the outside profile and radius of their snap fit measured on their product’s new cylinders. Something just wasn’t right. We used our optical comparator and a vision system to get them the data they needed to overcome

Read More