Medical Industry

Made to Measure has been inspecting medical parts, devices, equipment and components for over 35 years. We not only have a vast array of equipment, but a team of Metrologists unrivaled in the industry. Read more about our dedication to the medical manufacturing industry and how we can support you. Call or email us to learn more or request a quote.

ISO Accreditations/ASME Certifications

Made to Measure supports and understands ISO13845 requirements. Made to Measure’s ISO accreditations include ISO 17025 for dimensional measurement and ISO 17025 for dimensional calibration. Additionally, our senior level Metrologists are ASME GDTP certified, the highest level of proficiency in geometric dimensioning and tolerancing principles offer by the American Society of Mechanical Engineers.

Form, Function, & Comfort

With most components, form and function is the only concern. With medical devices, we appreciate the special requirement to perform comfortably as well. We fully grasp that the importance of the dimensional inspection and analysis performed holds an extra level of urgency. That’s why we take extra care to make sure the inspection data is right and meaningful.

Special Handing Requirements

When requested, Made to Measure Metrologists will handle and inspect medical components with any required PPE including gloves, masks, face shields, and protective suits. Non-contact inspections are also available. In addition to our stable, climate controlled laboratory conditions, our staff can take extra precautions to eliminate contaminates from the environment by creating a temporary cleanroom.

Transparency of approach, process, and accuracy

Whether we are working with a medical components manufacturer or an aerospace company, Made to Measure automatically documents and shares how we capture the data in your report and provides traceability. From the Metrologists who worked on your project to the equipment used, we are fully transparent. We are open to adopting special reporting formats, following prescribed inspection processes, and using custom fixturing. If you would like to be at Made to Measure to observe the inspection of your components, we are happy to accommodate you and any colleagues you would like to attend. If you can’t attend, but would like to see the inspection, we can set up a camera or send video or pictures.

We Inspect All types of Medical Components

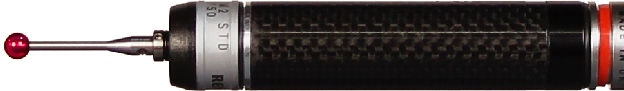

We are fully aware that not all medical components are the same. That’s why we have some many tools in our lab to inspect your components. We can inspect nearly any size, weight, or material and can handle complex geometries and super tight tolerances. We have at our disposal a wide range of CMMs, vision machines, CT scanners, laser scanners, and manual hand tools. Whatever you need inspected, we’re confident we can support your project.

Industry-Leading Metrologists

We have some of most experienced and well-trained Metrologists in the industry. They come from very diverse backgrounds ranging from plastic injection molding to machining. Our Metrologists have worked on thousands of projects involving most medical applications. We believe that with our experience, education, and training, we can provide you the best inspection service available.

Consulting & Training

When requested, our Metrologists take their expertise beyond the inspection of components by offering our clients consulting and training. We can review your drawings and make recommendation on how to best modify them or develop a new inspection process that you can take back to your lab. We also provide metrology training to medical companies across North America to help them enhance their metrology competencies. Whether you’re looking for consulting support or metrology training, please consider Made to Measure.

Fast Lead-Times/ Expedited & Emergency Service

Made to Made on average has 13 Metrologists on staff full-time. We can handle large influxes of inspections. When necessary, our team will commit more time to provide 2 to 3 day expedited service or 1 day emergency service.