Metrology Services | Dimensional Inspection & Measurement

Made to Measure has provided customers with CMM measurement and metrology services for professional dimensional inspection reports. We also offer CMM calibration and engineering services across countless industries, including: Aerospace, Medical, Defense, Space Flight, Automotive, Plastics, Commercial Products, and more. And

Whether you’re looking for 3D laser measurement, CMM FAI inspections, reverse engineering projects, or any other dimensional inspection services, Made to Measure can help.

Why Trust Our Metrology Services?

All of our metrologists are AUKOM Certified and come from diverse manufacturing and engineering backgrounds. We continually invest in our environmentally-controlled, ISO/IEC 17025:2017 accredited metrology lab to ensure we have the equipment needed for your inspection. Furthermore, we’re constantly updating our employees on their metrology training to stay informed on the fields of design, contour analysis, surface analysis, manufacturing, and contract inspection.

When you work with Made to Measure, we’re here to support your team with our CMM services and creative problem-solving to help you move quickly through the quality stage. From First Article Inspection to CMM Programming, we’re your go-to when you need a full-service metrology lab.

Our Metrology Lab Capabilities

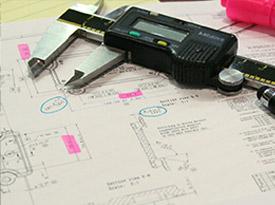

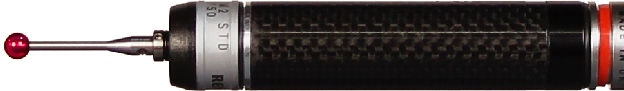

Because we’ve been offering metrology services for nearly 40 years, we’ve amassed a veritable arsenal of precision equipment. But what can we handle? Browse a few of our key capabilities at our metrology lab:

- 15 high-accuracy CMMs with measurement envelopes as large as 200” x 110” x 75”

- 3D Laser Scanning

- Industrial CT Scanning services

- Video optics measuring systems (VMM)

- Full complement of conventional inspection tools for roundness testing, form tracing, surface finish, and hardness

- A highly-experienced, diverse team of certified metrologists

Browse the Metrology Services Available at Made to Measure

Are you curious about everything offered at our metrology lab? Take a moment to peruse the metrology services offered at Made to Measure below. And of course, don’t hesitate to contact us online if you have any questions for our team. We’re always ready to take a look at your project and give you a quote for our CMM inspection services.

Measurement

Programming

Reporting