CMM, Vision, & Equator Programming | Made to Measure

While it may not be a full-time job for some, companies still need experienced and knowledgeable CMM, Vision, and Equator programmers to set up their machines. Effectively-programmed software ensures the correct use of datums & styli for the job at hand. Programming can help with production bottlenecks, personnel shortages, or assisting Metrologists and Operators with running parts they may not be familiar with.

Without an expert CMM, Vision, or Equator programmer on-hand, measuring equipment can pose unforeseen production issues, and this is not an uncommon problem. At Made To Measure, our Metrologists can code software for your team that your operators are familiar to work in the comfort of your own facility.

Our Metrologists Offer CMM and Vision Programming in Multiple Software

PC-DMIS MODUS Verisurf PolyWorks

CMM-Manager MCOSMOS CALYPSO

VDMIS ARCOCAD OGP BASIC X MICRO VU INSPEC Nikon iNEXIV

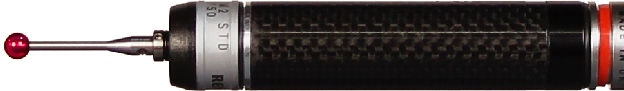

Plus, we have considerable experience creating CMM programs for most CMM software in conjunction with Renishaw’s REVO and REVO-2 Measurement System including MODUS and PCDMIS*

*PCDMIS limited to 3-axis scanning mode

Offline CMM, VMM, or Equator Programming

If you know you’re going to need a dimensional inspection, but the parts in question are still in production, then you may face potential setbacks without a dedicated CMM programmer. That’s where we step in!

Offline Programming Services help prevent delays in manufacturing by programming the software ahead of production. First, we examine the manufacturing drawings and CAD models of any parts that need to be measured. Once our certified metrologists are familiar with your parts, they begin coding a program to inspect them post-production. We can even prepare your CMM programs before the tooling is even completed, saving you valuable time between production and inspection.

Meanwhile, your in-house quality control department can prevent bottlenecks when it comes time to inspect the parts. When you have a program ready and in-place, all you need to do is run the parts. Offline CMM, VMM, or Equator Programming at Made to Measure can also help your team optimize accuracy—ultimately maximizing the ROI of your coordinate measuring machine, vision machine, or Renishaw Equator Gauging System by increasing throughput and reducing strain.

Get a Quote for CMM, VMM, or Equator Programming Today!

Are you ready to request a quote for programming? We’ll need a drawing of the part being manufactured, a CAD model, and your in-house machine specs, including:

- Type of Machine

- The Controller

- Probes and Probe tips specifications

- Pre-established fixturing to hold the part

Why wait? Plan your next inspection today and let our offline programming services boost your efficiency. We will help you in every step of the process, so don’t hesitate request a CMM programming quote when you’re ready.

Renishaw MODUS™ Equator Programming

With the power and knowledge of our metrology team, we can create programs with MODUS™ Gauging Software for your team to run on your Equator in-house. On the programmable system, the comprehensive MODUS™ programming software allows our metrologists to rapidly create gauging routines for any part – simple or complex; prismatic or free-form.

MODUS™ features the ability to program scanning and touch measurements easily on the Equator system, using the industry-standard SP25 probe. Scanning enables thousands of data points to be taken to define a feature, allowing true form analysis. We strive to fit your timeline and work with you until your team has the tools they need to succeed.

Our Metrologists are knowledgeable in the following software:

CMM PROGRAMMING

- REVO/REVO-2

- PC-DMIS

- MODUS

- Verisurf

- CMM-Manager

- MCOSMOS

- Calypso

- VDMIS

- ARCOCAD

- PolyWorks

VISION MACHINE PROGRAMMING

- MICRO VU INSPEC

- OGP BASIC X

- Nikon iNEXIV

- CMM-Manager

EQUATOR PROGRAMMING

- MODUS

What do you need to get a quote?

– A drawing of the part being manufactured – A CAD Model – Your In-House Machine specs including:

- Type of Machine

- The Controller

- Probes and Probe tips specifications

- Pre-established fixturing to hold the part